FLTF - 800 Tunnel Freezer

The 800kg Tunnel Freezer delivers efficient and rapid freezing for medium-scale food processing, ensuring optimal product quality with energy-saving performance.

online message

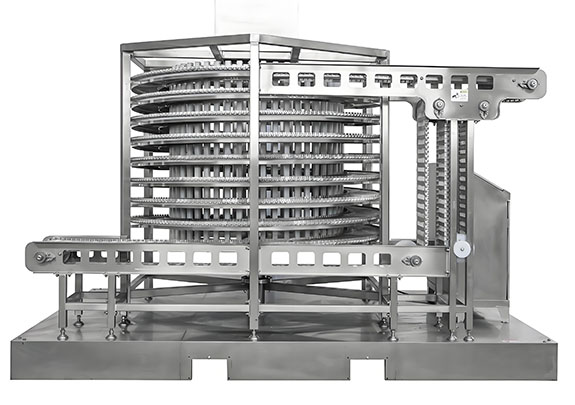

Our spiral freezer is a space-saving freezing solution that delivers high-capacity output within compact footprints. This innovative equipment achieves remarkable production efficiency with an hourly output ranging from 500kg to 5000kg, making it ideal for facilities with limited space but demanding throughput requirements. Featuring advanced spiral belt technology, it ensures rapid, uniform freezing while maintaining product quality through precise temperature control, suitable for processing meat, seafood, vegetables, and prepared meals.

The 800kg Tunnel Freezer delivers efficient and rapid freezing for medium-scale food processing, ensuring optimal product quality with energy-saving performance.

The 1500kg Tunnel Freezer offers high-capacity freezing power, ideal for large-scale production, combining speed, uniformity, and reliability for industrial food preservation.

High-Efficiency Evaporator

Full aluminum alloy or stainless steel fins, hygienic-grade design with variable fin spacing for efficient defrosting and reduced defrosting time.

Stable Transmission System

Proprietary spiral transmission mechanism. The belt is constructed with SUS304 high-elasticity, high-toughness spring wire. Unique flight bar design ensures stable conveying of food products.

Thermal Insulation Chamber

150mm thick high-density polyurethane insulation panels with dual-sided SUS304 stainless steel skins. Excellent thermal insulation performance minimizes cold loss.

Fully Automated Belt Sensing System

Automatically detects belt flipping and slackening, enabling timely adjustment to minimize operational losses.

Water Tank Drainage Design

Integrated stainless steel water tank with leak-proof structure. Optimized drainage design features a rational slope gradient to ensure thorough cleaning, efficient drainage, safety, and hygiene.

This high-efficiency spiral freezer is designed for rapid freezing of diverse food products, including:

Meat & Poultry: Sliced/diced beef, chicken cuts, bone-in/deboned products.

Seafood: Fish fillets, shrimp, scallops, surimi-based items (e.g., fish balls).

Prepared Foods: Dumplings, spring rolls, fried snacks, and ready-to-cook meals.

Fruits & Vegetables: Berries, diced produce, and mixed vegetables.

Specialty Items: Mushrooms, bakery fillings, and herbs.

A spiral freezer is a continuous industrial freezer that uses a vertically spiraling conveyor belt to efficiently freeze food products via blast freezing.

Uses powerful jets of cold air to suspend and freeze individual small food particles (like peas or berries) quickly and separately.

Freezes products rapidly through direct contact between the product (often in blocks or packages) and refrigerated metal plates.

A large, insulated walk-in chamber designed to freeze stationary batches of packaged or palletized products over a longer period.

Foodline Machinery specializes in designing, manufacturing, and installing quick-freezing, freeze-drying, drying, and sterilization equipment for food processing. Its products are widely used in seafood, fruits, meat, pasta, and prepared foods.

With 20+ years of industry experience, the company has a strong R&D team and advanced manufacturing capabilities, delivering high-performance solutions like tunnel freezers, spiral freezer, plate freezers, and freezing rooms. Its projects have earned consistent customer acclaim.