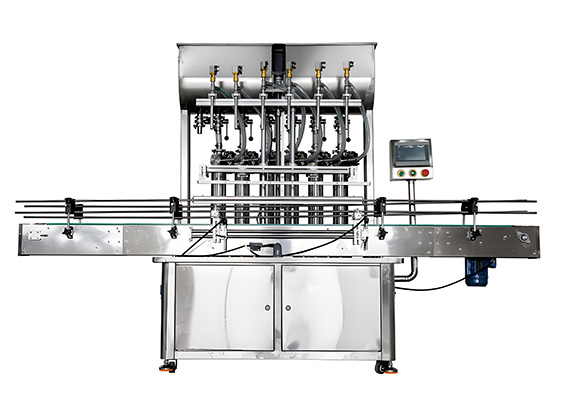

Fully Automatic Rotor Pump Filling Machine

Engineered for particle-thickened fluids. ±5g accuracy at 1-50 bottles/min. Perfect for pastes, adhesives & particle sauces in food, cosmetics & industrial use.

online message

A liquid filling machine is a device that repeatably fills containers (like bottles or jars) with liquid from a larger source (such as an IBC tank or hopper), dispensing a predetermined volume via a nozzle. Available in diverse types designed for specific production scales, filling methods, volumes, liquids, and viscosities, these machines handle quantities ranging from a few jars to tens of thousands of bottles. Smaller units may be manually operated or semi-automatic (powered by air, electricity, or both), and they are used widely across industries including water, cosmetics, solvents, and paints.

Engineered for particle-thickened fluids. ±5g accuracy at 1-50 bottles/min. Perfect for pastes, adhesives & particle sauces in food, cosmetics & industrial use.

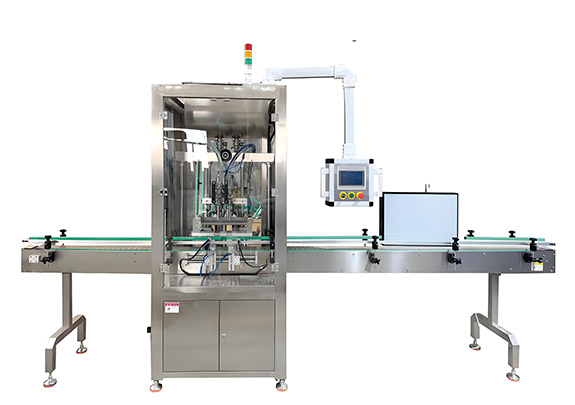

Full-automatic Servo Plunger Filler for ±1% precision dosing of low-medium viscosity liquids & creams in food, pharmaceutical, and cosmetic applications (50-5000ml, 2-12 heads, 10-35 bottles/min).

Fully automatic double-head servo filling machine for ±1% precision packaging of low-viscosity liquids & creams in household, food & industrial applications (50-5000ml, 10-20 bottles/min).

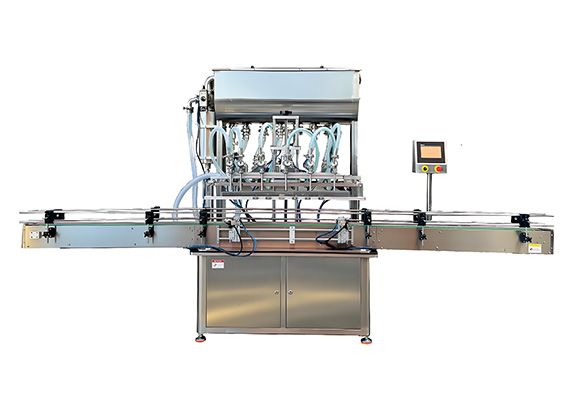

Full-automatic gear pump filling machine for 0.3%-1% precision packaging of low-viscosity liquids (100-10000ml, 1-50 bottles/min) in household, food & industrial applications.

Fully automatic paste filling machine with multi-nozzle synchronous dosing for ±1% precision packaging of fluids & semi-fluids in food, cosmetic, pharmaceutical & chemical industries (500-5000ml, 15-30 bottles/min).

Precision liquid filler for bubble/particle-free aqueous solutions (food/cosmetics/pharma). Custom capacity 50-5000ml, speed 10-20 bottles/min, ±1% accuracy.

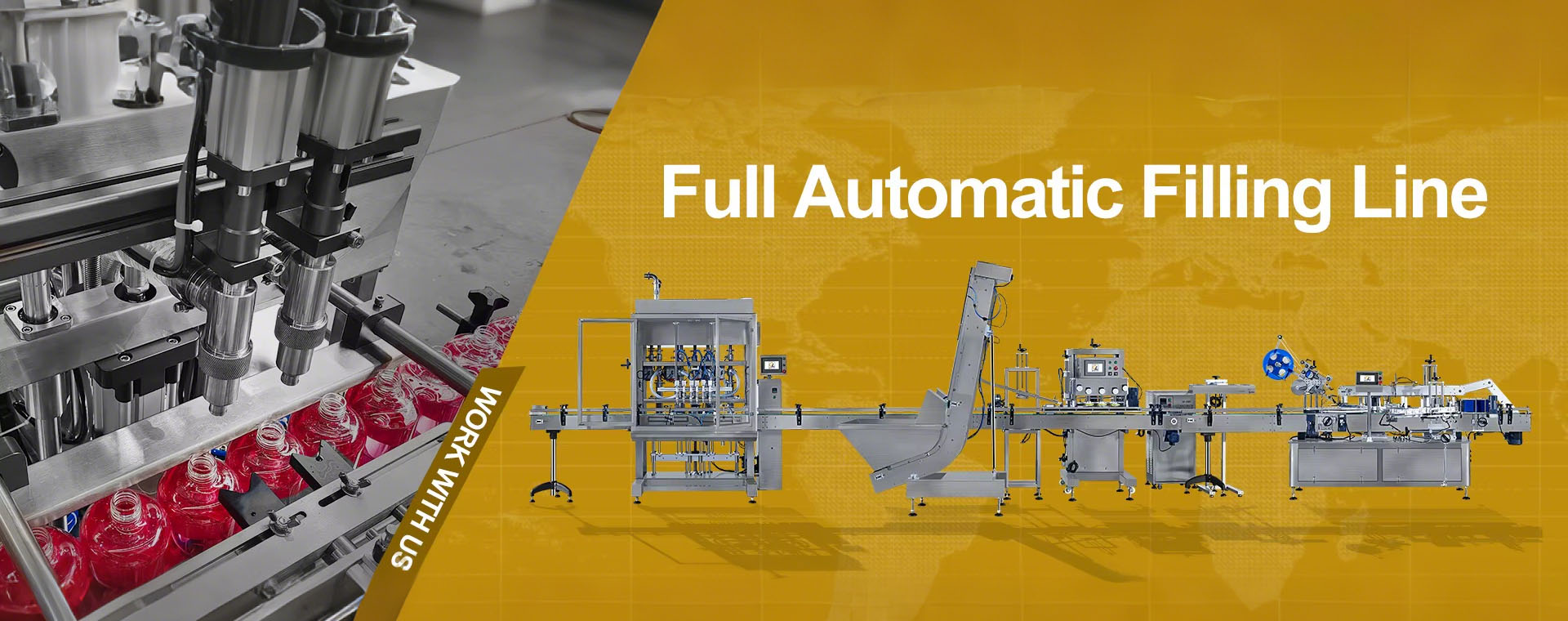

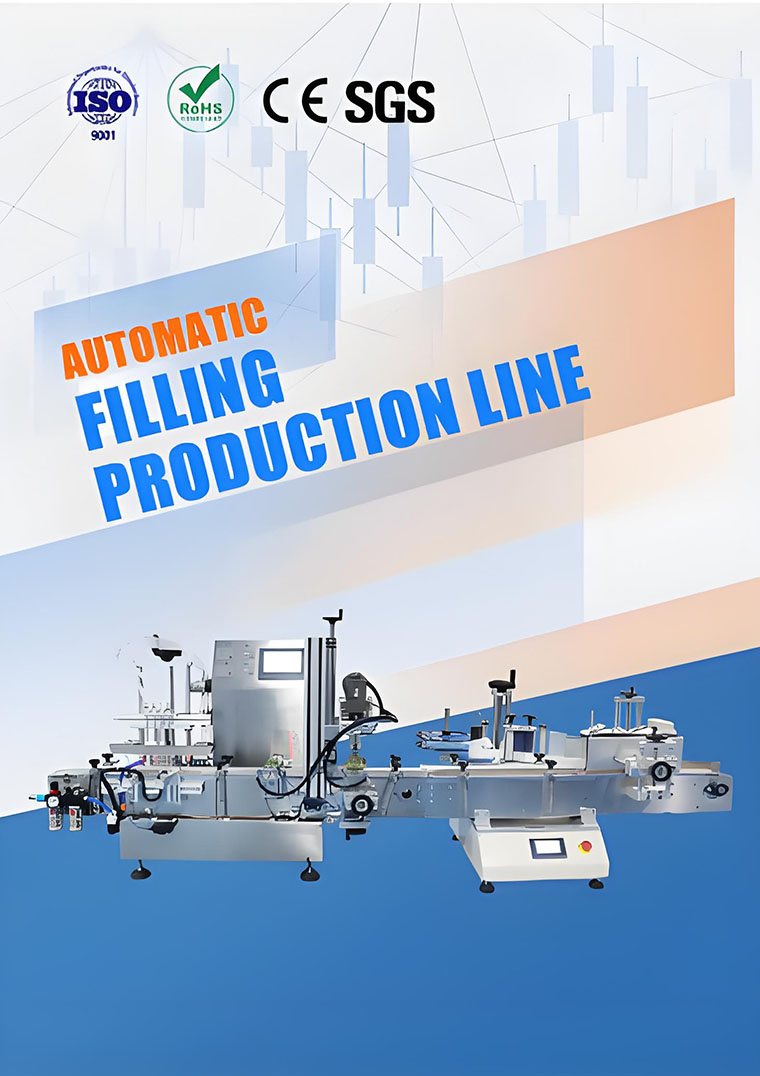

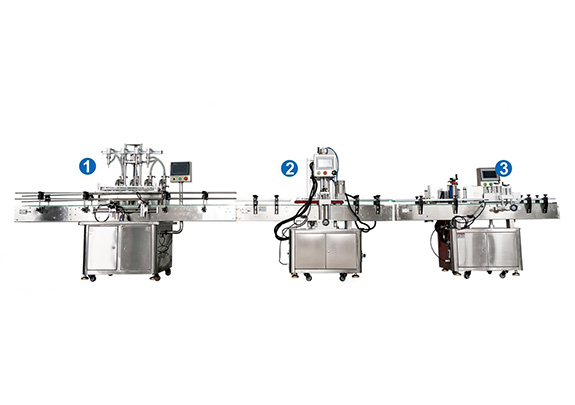

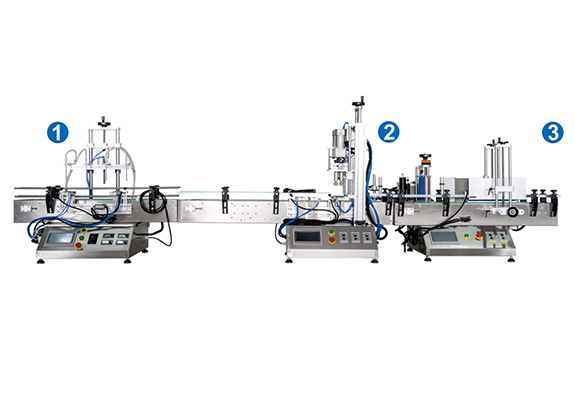

Integrated filling-capping-labeling system for liquid packaging (20-40 bottles/min, ±1% accuracy), customizable for food to chemical industries.

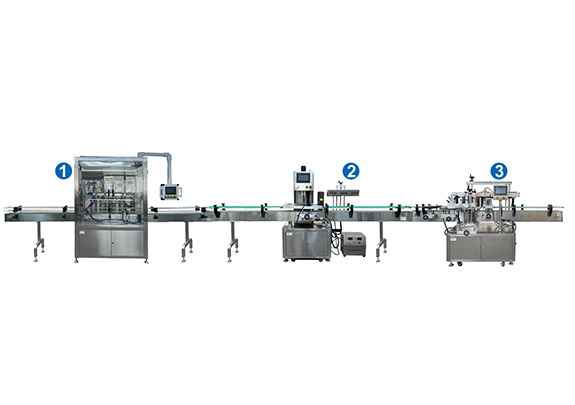

All-in-one packaging solution for food to pharma, handling fluids/semi-fluids (honey to toothpaste) with 50-5000ml customizable filling and ±1% precision.

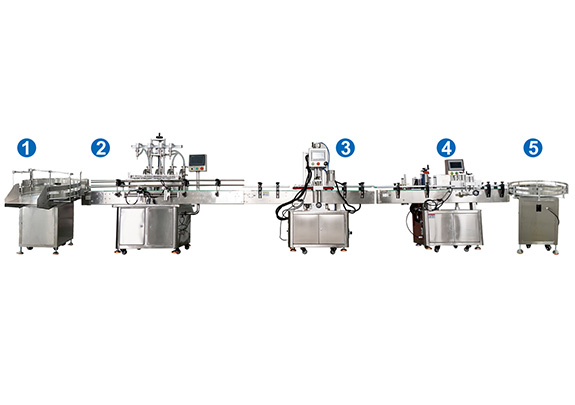

Automated bottle sorting-filling-capping-labeling system for pastes, liquids & particle suspensions (50-5000ml customizable), achieving ±1% accuracy at 40 bottles/min, ideal for cosmetics, food and beverage industries.

Hygienic filling-capping-labeling system with magnetic drive, customizable for sterile liquids (vaccines to essential oils) at 20-40 bottles/min, compliant with GMP standards.

1. Ultra-High Precision & Consistency

±0.2% filling accuracy with servo-driven control, ensuring uniform volume across batches (critical for pharmaceuticals/cosmetics).

Auto-compensation for viscosity/temperature variations.

2. Industry 4.0 Smart Integration

IoT-enabled remote monitoring & predictive maintenance (reduce downtime by 30%).

MES/ERP compatibility for real-time traceability (meets FDA/CE/GMP standards).

3. Hygienic & Aseptic Assurance

CIP/SIP systems (no disassembly cleaning) + ISO 5 cleanroom-grade filling zone.

Dry-contact valves for sterile-sensitive products (e.g., vaccines).

4. Flexible Production Adaptability

Quick-change modules (under 5 mins) for bottles/pouches of any shape/size.

Multi-mode filling: Gravity/Pressure/Vacuum for diverse liquids (water to thick pastes).

5. Energy-Efficient & Sustainable

Servo energy recovery cuts power consumption by 35%.

Low-waste design: Drip-free valves + recyclable materials.

Our filling machines are expertly engineered to handle a wide spectrum of liquid types for diverse production requirements:

Normal Liquids

(e.g., mineral water, liquor, edible oil, liquid fertilizer)

Foamy Liquids

(e.g., red wine, soy sauce, vinegar, fermented beverages like rice wine)

Carbonated Liquids

(e.g., beer, cola, soda, sparkling water)

Liquids with Suspensions

(e.g., pulp juices, fruit-containing drinks, emulsions)

Hazardous Liquids

(e.g., flammable alcohols, corrosive acids/bases, toxic reagents like formaldehyde)

High-Viscosity Liquids & Pastes

(e.g., honey, syrups, sauces, cosmetic creams, shampoos)

Full-automatic 4-wheel capping machine for pumps/spray heads (20-100mm), with adjustable torque & speed (35pcs/min), suits pharmaceutical to cosmetic lids via electrical-pneumatic control (220V/50Hz).

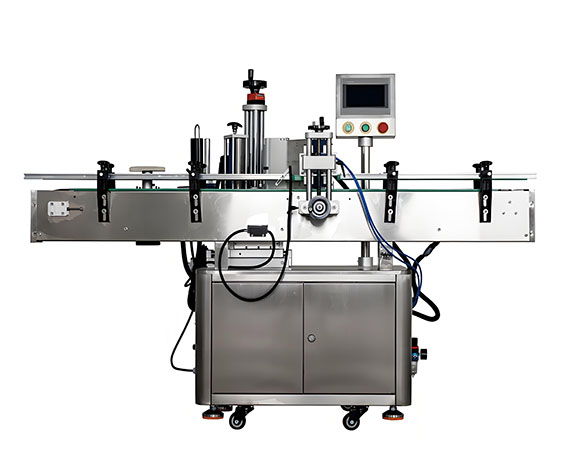

Industrial-grade auto labeler handles conical/round bottles (H230mm max), featuring precision alignment (±1mm) and 15-45pcs/min speed under 50Hz power.

Integrated filling & hermetic sealing machine, featuring volumetric accuracy (±1%) and 30pcs/min speed under 220V/50Hz, ensures leak-proof packaging.

High-speed PET blowing machine for 100-2000ml bottles, achieves 2,000pcs/hr with servo-driven stretch-blow molding, compatible with 4-cavity molds under 380V/50Hz.

Foodline Machinery specializes in the R&D and manufacturing of automated filling & labeling equipment, as well as integrated smart production line systems. Guided by our philosophy of "Professional dedication to delivering efficient automation solutions", our experienced design team leverages extensive industry expertise to provide tailored turnkey solutions for food, beverage, pharmaceutical, cosmetics, electronics and logistics sectors. Through continuous technological innovation, we keep upgrading our equipment to meet evolving market demands.