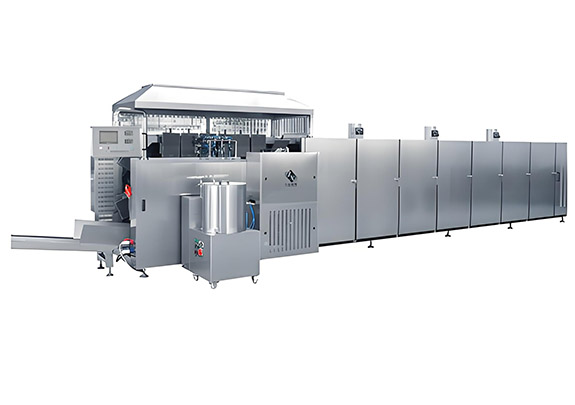

Small Biscuit Production Line

Compact and efficient equipment designed for high-output manufacturing of bite-sized biscuits with precise texture control.

online message

Cookies can be categorized into hard biscuits, shortbread biscuits, and cookies based on their recipes, production processes, and shaping methods. A hard biscuit production line typically consists of a feeder (with an additional lamination step for soda crackers or cream crackers), a set of dough rollers for sheeting, a rotary cutter, a scrap recycling device, and an oven loader to complete the forming process. Shortbread and cookie production lines only require a forming machine and an oven loader. To diversify products, optional equipment like salt/sugar sprinklers, egg sprayers, egg brushes, or imprinting machines can be added.

Compact and efficient equipment designed for high-output manufacturing of bite-sized biscuits with precise texture control.

A complete automated system integrating mixing, shaping, baking, and packaging for seamless large-scale biscuit production.

Specialized machinery for creating uniform cookie shapes (e.g., rounds, squares) with adjustable thickness and patterns.

End-to-end automation solution ensuring consistent quality, speed, and hygiene in industrial biscuit manufacturing.

Innovative & Compact Design: Features modern design with high automation and space-saving structure.

Fully Automated Process: Integrates all steps (feeding, rolling, forming, waste recycling, drying, oil spraying, cooling) into one seamless workflow.

Modular Flexibility: Shortbread/tough biscuit lines can be customized for any workshop layout or production requirements.

Premium Components: Equipped with imported electrical parts, variable frequency speed control, and energy-saving technology (supports both individual/centralized control).

Versatile Production: Compatible with molds/recipes to produce trending biscuits: Cream-filled, sandwich, ultra-thin, soda crackers, animal-shaped, multigrain, vegetable-enriched varieties

Reliable Performance: Ensures consistent quality with stable operation and low maintenance.

We provide complete biscuit production solutions from small semi-auto to industrial fully-automated lines, specializing in shortbread, cookies, sandwich, and shaped biscuits (e.g., bear cookies). Our modular systems enable quick product switching with energy-efficient operation, reducing labor costs by 40% while maintaining quality. Compact machines suit artisanal producers, while high-speed lines (up to 5,000kg/hour) meet mass production needs with ISO 22000 compliance. Ideal for startups to global brands seeking versatility (gluten-free/functional options) and cost efficiency.

A high-efficiency line for producing creamy-filled sandwich biscuits with consistent layering and flavor.

Designed to bake thin, crispy biscuits with uniform texture and golden appearance.

Specialized equipment for shaping and baking adorable bear-shaped biscuits, ideal for kids' snacks.

A turnkey solution for mass-producing soft, fluffy cakes with minimal manual intervention.

Foodline Machinery specializes in high-efficiency biscuit production equipment, offering tailored solutions from compact semi-automatic machines to large-scale automated lines. Our expertise covers shortbread, cookies, sandwich biscuits, and shaped varieties, with modular designs for quick product switching and ISO 22000 compliance. Ideal for startups to OEMs, our energy-saving systems boost output (up to 5,000kg/hour) while cutting costs by 40%. Partner with us for reliable, scalable biscuit manufacturing technology.