Air Bubble Washing Machine

Air Bubble Washing Machine: The Air Bubble Washing Machine generates millions of tiny air bubbles through an advanced air injection system, gently lifting and washing away dirt while being gentle on delicate fabrics.

online message

This fruit and vegetable washing machine uses bubble surfing, brushing, and spraying technology for maximum cleaning efficiency. It features a bubble generator, VFD for belt speed adjustment, a separate filter tank, water recycling system, and a spraying section for twice washing. Suitable for various processing scales, it offers capacities ranging from 100-3000kg/hour and is indispensable for fruit, vegetable, or seafood processing.

We offer a range of fruit and vegetable washing machines, including bubble washers, vortex washers, and brush roller peelers/washers.

Air Bubble Washing Machine: The Air Bubble Washing Machine generates millions of tiny air bubbles through an advanced air injection system, gently lifting and washing away dirt while being gentle on delicate fabrics.

Eddy Current Washing Machine: The Eddy Current Washing Machine utilizes high-speed rotating eddy currents to effectively remove impurities and achieve thorough cleaning with minimal water usage.

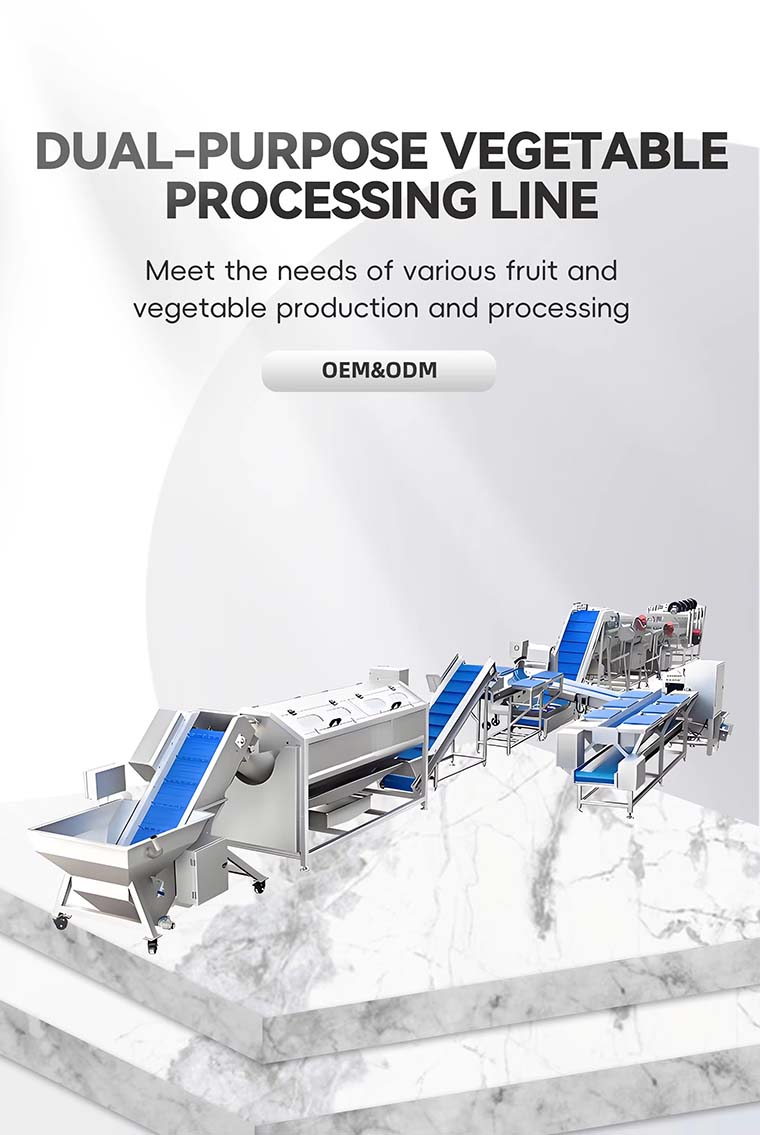

The CLEAN VEGETABLE PROCESSING LINE is a fully automated system designed for efficient and hygienic vegetable processing. It integrates washing, sorting, cutting, and packaging stages, ensuring high-quality output with minimal manual intervention.

Leafy Vegetable Processing Line: An automated solution for efficient cleaning, cutting, and packaging of fresh leafy greens, ensuring high-quality output for food production.

Rinzome Processing Line: A specialized system designed for precise handling and processing of root vegetables, optimizing productivity and product consistency.

1. Equipped with a bubble generator to make the objects roll over High pressure air bubble and spraying water can wash off dirt, sands and other residues.

2. Equipped with VFD to better adjust the belt speed.

3. Equipped with separate filter tank and water recycling system.

4. Equipped with spraying section with clean water for twice washing . The objects are automatically conveyored to spraying section by the conveyor mesh belt.

First, all the vegetables that need to be cleaned are put into the sink, and under the action ofhigh-pressure water flow and strong air bubbles, they are fully dispersed, rolled, ceanedand transported. The mud and sand on the surface of the vegetables will fall off, and themesh belt cleaning machine will settle to the bottom isolation bin to prevent re-pollutioncaused by backflow.

Equipment Cleaning Scope:

1. Vegetable bubble cleaning machine: peppers, vegetables, ginger, etc.

2. Fruit bubble cleaning machine: apples, pears, plums, plums, etc.

3. Bubble cleaning machine for medicinal materials: platycodon, asarum, gastrodia elata,planted ginseng, etc., including roots, stems and leaves.4. Candied fruit bubble cleaning machine: grapes, hawthorns, red dates, green plums, sand fruits,strawberries, etc.

A complete solution for frozen vegetable production, from cleaning to freezing, ensuring high-quality output.

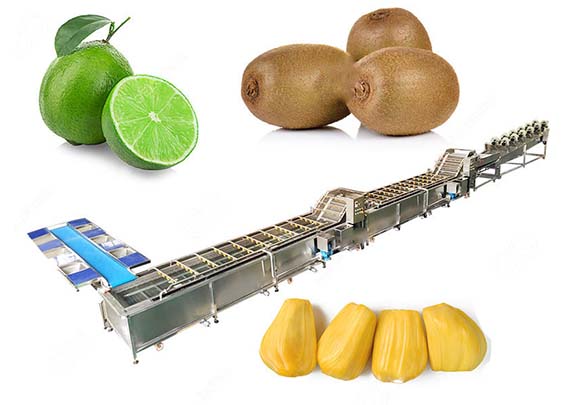

Efficiently washes and sorts fruits by size and quality, ideal for fresh produce markets.

Combines washing and drying in one seamless process, perfect for moisture-sensitive vegetables.

Specialized for ready-to-eat vegetables, featuring thorough cleaning and minimal handling.

Foodline Machinery is a leading manufacturer of fruit and vegetable processing equipment, offering end-to-end solutions for fresh-cut, frozen, dried, and sorted produce lines. Since 2005, we've served 6,000+ enterprises in 180+ countries with reliable technology and responsive support, backed by CE & ISO certifications and 24/7 service.